ADVANCEMENT OF ANOTHER DEFINITION FOR DIRECT PRESSURE OF A CHARACTERISTIC ITEM

Commentary - (2021) Volume 10, Issue 2

Abstract

Keywords

Improvement, detailing, direct pressure, plan of trial, quality by plan

This exploration project comprised in fostering another definition for the immediate pressure of senna – a naturally non-compressible material starting from the dried cases of a plant named Cassia acutifolia. The test of finding sufficient excipients to pack senna was consolidated to the test of keeping up with comparable weight and appearance to that of the at present promoted senna tablets. These difficulties originated from the way that the current detailing is made out of 80% senna, which made critical constraint for presenting compressible excipients. To beat these difficulties, right now advertised senna tablets are for the most part produced through wet granulation before pressure, an interaction that is fairly arduous and expensive. The water goes about as a cover in the granulation cycle, which permits the tablets to keep up with their solidarity and trustworthiness. Nonetheless, wetting, drying and testing the granules for measure includes extensive time, work and apparatus when contrasted with the immediate pressure measure. Notwithstanding cost investment funds, direct pressure doesn't need water or warmth all the while, which might actually diminish hydrolysis and oxidation of the dynamic standard and upgrade item strength. The improvement of senna definition for direct pressure was led in six trial plans, where bunches of senna tablets were produced according to explicit lattices and dissected for hardness, friability, breaking down, appearance, normal weight, dampness and test, as the venture advanced. The outcomes were contrasted with characterized details which depended on the as of now advertised senna tablets.

Introduction

The goal of this exploration project was to foster another definition for the immediate pressure of senna – an inherently non-compressible powder that begins from the dried units of a Middle Eastern plant named Cassia acutifolia – known for quite a long time in the treatment of infrequent blockage [1]. The dynamic standards found in senna powder are called sennosides and produce restorative outcome by means of aggravation of the inward layer of the gastro-intestinal parcel, subsequently initiating solid discharges [2]. Retention of senna through the cells exhibits direct and positive outcomes displayed by Waltenberger et al. [3]. In any case, ingestion isn't totally needed as the helpful impact is created by the sole presence of senna in the gastro-intestinal lot [2]. A reliable interest for the regular source senna tablets comes from different networks like the seniors, grown-ups, pregnant ladies and youngsters who experience the ill effects of periodic stoppage. Senna tablets have been widely depicted in Pharmacopeias, Compendium of Pharmaceutical Specialties and the Merck Index and keep on tracking down an upper hand over items from engineered sources, for example, bisacodyl and docusate sodium that offer comparative treatment. The target of this exploration project was to foster another definition for the immediate pressure of senna – a naturally non-compressible powder that starts from the dried cases of a Middle Eastern plant named Cassia acutifolia – known for quite a long time in the treatment of infrequent clogging [1]. The dynamic standards found in senna powder are called sennosides and produce restorative outcome by means of bothering of the internal layer of the gastro-intestinal lot, in this way initiating defecations [2]. Ingestion of senna through the cells exhibits straight and positive outcomes displayed by Waltenberger et al. [3]. In any case, retention isn't totally needed as the helpful impact is created by the sole presence of senna in the gastro-intestinal plot [2]. A reliable interest for the regular source senna tablets comes from different networks like the older folks, grown-ups, pregnant ladies and kids who experience the ill effects of infrequent stoppage. Senna tablets have been broadly depicted in Pharmacopeias, Compendium of Pharmaceutical Specialties and the Merck Index and keep on tracking down an upper hand over items from manufactured sources, for example, bisacodyl and docusate sodium that offer comparable treatment .

Materials and techniques

Materials

Eleven excipients were selected based on their organic properties, particle size, density, compressibility, flowability, mode of compression and water solubility in order to optimize powder compatibility, blend uniformity, tablet appearance, tablet weight, tablet hardness, tablet friability and tablet disintegration [9-16]. A mixture of excipients commonly used as binders, diluents, fillers, disintegrant and hardness enhancers were purposely selected to achieve these goals. The excipients were acquired from commercial suppliers such as DOW, FMC Biopolymer, Roquette and were labelled X1 to X11 as follows for design of experiment purposes.

Pregelatinised starch (X1), microcrystalline cellulose (X2), lactose monohydrate (X3), sorbitol (X4), ethylcellulose (X5), hydroxyethyl cellulose (X6), hydroxypropyl cellulose (X7), methylcellulose (X8), hydroxypropylmethyl cellulose (X9), ethylcellulose from a different supplier than X5 (X10) and alginic acid (X11).

Methods

Quality by plan (QbD)

As a feature of QbD, the "Quality Target Product Profile" (QTPP) displayed in Table 1 was set up dependent on the current maker's details for senna tablets. The QTPP was utilized as a manual for make a comparative item profile to accomplish comparable helpful impact.

Plan of analyses (DOE)

In order to find a new formulation for the direct compression of senna, several experiments with different combinations of excipients were attempted. The first set of experiments was conducted as per the Plackett-Burman design

Assembling measure

A similar assembling cycle and cluster size were utilized inside every DOE to limit varieties inside clumps. To satisfactorily evaluate the conduct of bigger powder mixes in the hardware, cluster sizes between DOE were progressively expanded from 50 grams (g) to 500 g from the Plackett-Burman plan to the halffactorial plan and afterward again to 1 kilogram for the four ensuing DOE. Mixing of fixings was performed physically for two minutes by tumbling in polyethylene packs for the twelve analyses of the Plackett-Burman plan, then, at that point naturally with a little V-Blender at 30 turn each moment (rpm) for 20 minutes for the seventeen trials of the half-factorial plan, and afterward with a 18 liters limit V-Blender at 50 rpm for 50 minutes for every resulting test. Grease mixing was performed for a span of 5% of the all out mixing time utilized in each particular plan preceding tabletting with the computerized Fette Press 1200i [Leitz Metalworking Technology Group, Fette compacting Rockaway.

Results and Discussion

In the main arrangement of analysis directed according to the Plackett-Burman plan network, five basic excipients were chosen for additional preliminaries: lactose monohydrate, sorbitol, hydroxypropyl cellulose, hydroxyethyl cellulose and methyl cellulose. In the second arrangement of investigations led according to the halffactorial plan, methyl cellulose was killed from additional preliminaries since no ideal impact was seen on tablet properties when this specific excipient was available in the detailing. Then again, lactose monohydrate, sorbitol, hydroxypropyl cellulose and hydroxyethyl cellulose were held for additional preliminaries.

Conclusion

The force of QbD and DOE techniques were instrumental in the revelation of the new plan advanced in this examination project. This methodology permitted the formulator to painstakingly choose the best excipients for the definition dependent on factual examinations acted in a consecutive way. Beyond anyone's expectations, the six DOE portrayed in this venture could be utilized again to foster other testing plans including a lot of non-compressible materials.

Author Info

VALLEJO MAROTO*Published: 30-Jun-2021

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

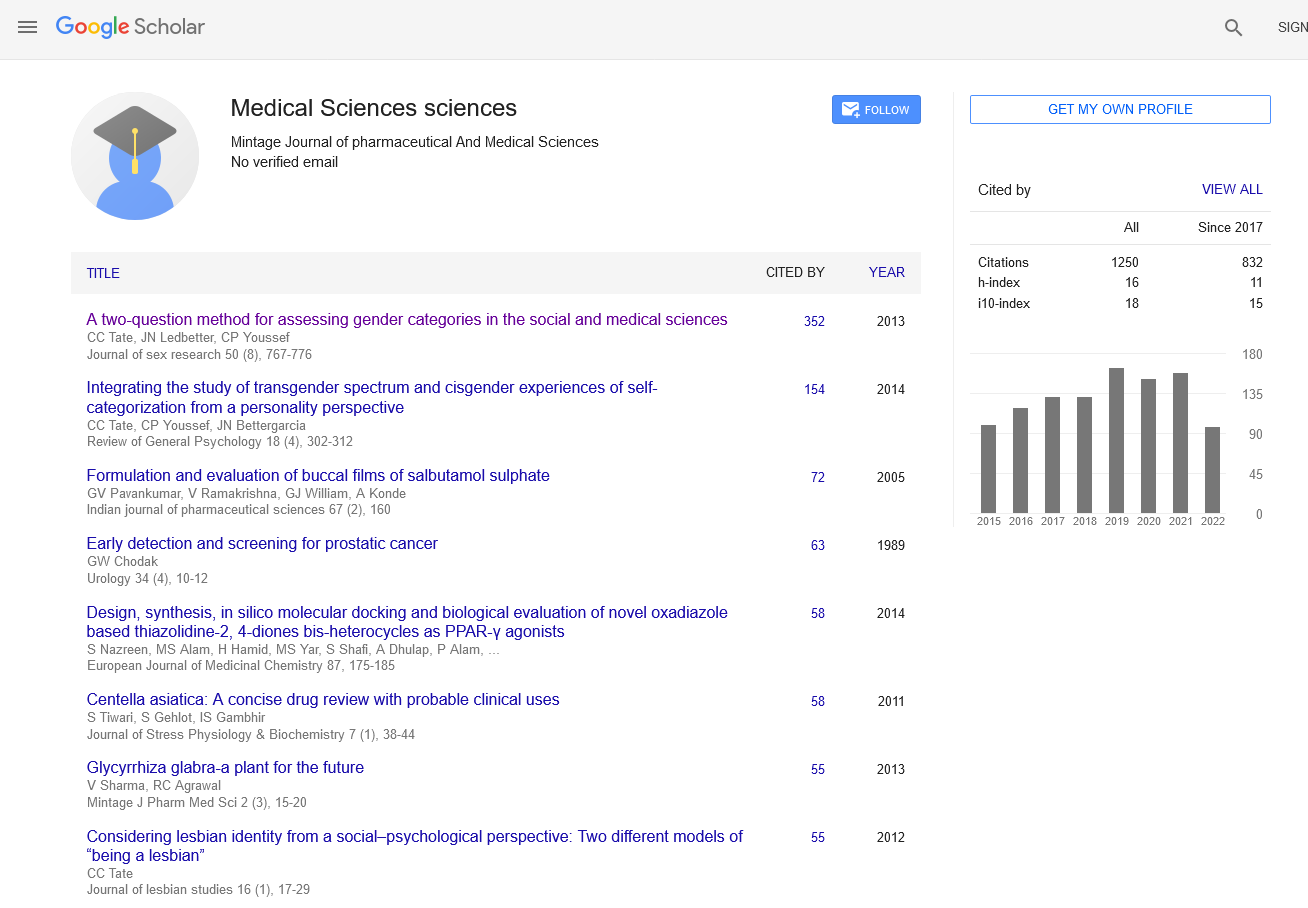

ISSN: 2320-3315

ICV :81.58